Publish Date

2024-01-09

The quest for efficiency has become a driving force for businesses seeking sustainable growth. Central to this pursuit is the optimization of operation settings, a multifaceted approach that involves fine-tuning equipment, processes, and workflows to achieve maximum efficiency. In this blog post, we will delve into the strategies and principles that underpin the optimization of operation settings, exploring how businesses can elevate their performance and thrive in an ever-evolving market.

Understanding Current Operation Settings

A thorough understanding of existing operation settings is paramount to embark on the optimization journey. Businesses must comprehensively assess their equipment, machinery, and operational processes. This involves identifying key performance indicators (KPIs) such as energy consumption, production output, and resource utilization. This initial step sets the stage for a targeted and informed optimization strategy.

Analyzing Efficiency Metrics

Efficiency metrics serve as the compass guiding businesses toward their optimization goals. Three core dimensions—energy efficiency, production efficiency, and time efficiency—form the basis for analysis. Benchmarking against industry standards provides valuable insights, helping businesses understand their standing in comparison to peers. This analysis also uncovers bottlenecks and inefficiencies, allowing for strategic adjustments.

Data Collection and Monitoring

Data is a powerful ally in the quest for efficiency. Implementing monitoring systems equipped with IoT devices and sensors enables real-time data collection. Advanced software solutions then analyze this data, providing actionable insights. Combining data-driven decision-making and automation empowers businesses to make informed adjustments on the fly, ensuring continuous optimization.

Adjusting Equipment and Machinery Settings

Calibrating and maintaining equipment is a fundamental aspect of operation settings optimization. Fine-tuning operational parameters, such as speed, throughput, temperature, and pressure, is equally crucial. Businesses can leverage intelligent technologies to achieve this, integrating sensors and automated systems that adapt to changing conditions. The result is a more responsive and efficient operation.

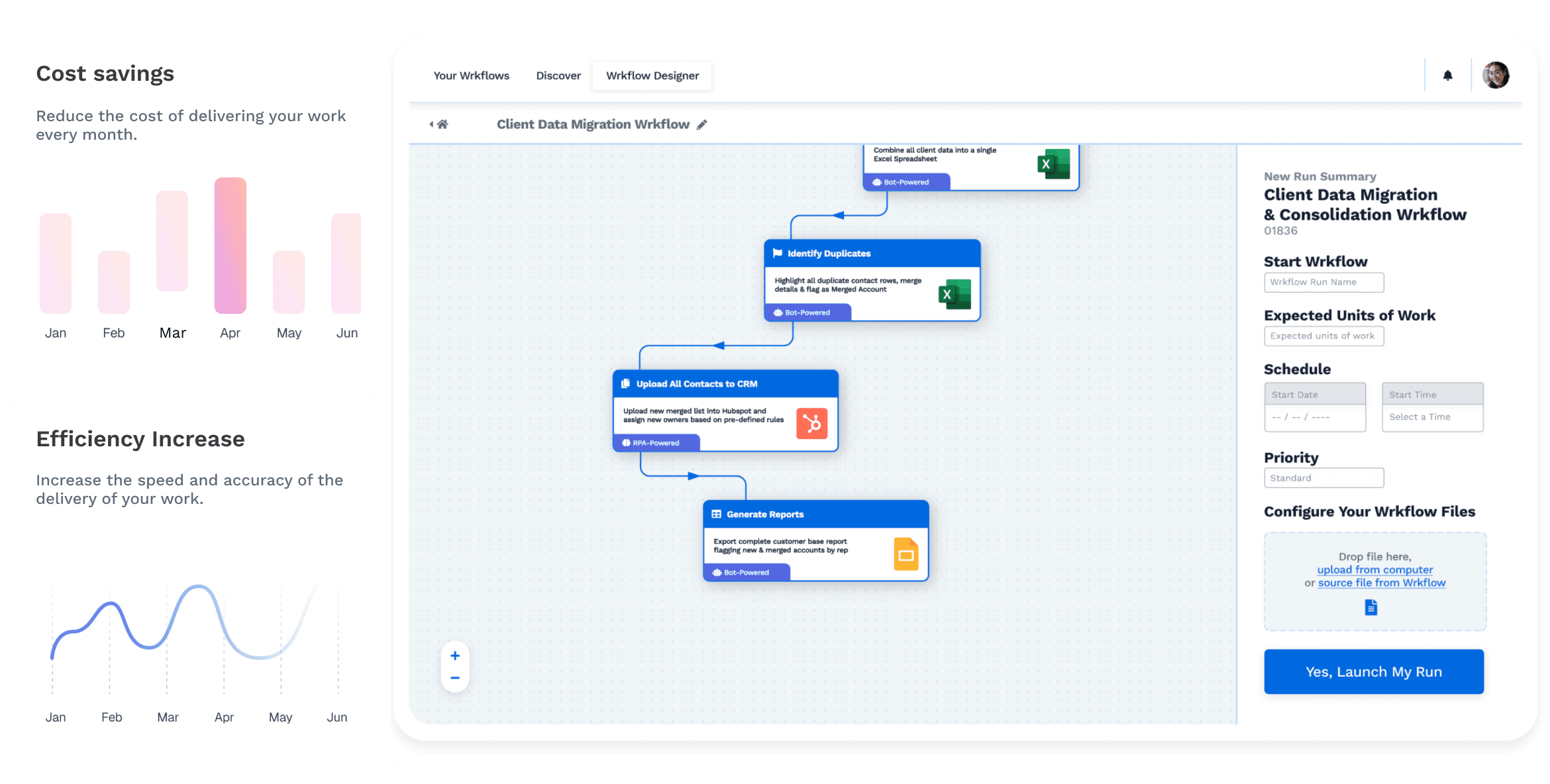

Streamlining Workflows and Processes

Efficient workflows are the backbone of any successful operation. Implementing lean manufacturing principles involves identifying and eliminating redundancies, reducing waste, and enhancing overall efficiency. Automation and robotics play a pivotal role in streamlining processes, with collaborative robots (Cobots) and autonomous systems taking on repetitive and time-consuming tasks, allowing human resources to focus on more complex and strategic activities.

Implementing Sustainable Practices

Efficiency and sustainability go hand in hand. Businesses are increasingly recognizing the importance of adopting eco-friendly technologies and strategies. From reducing waste to integrating renewable energy sources, sustainability initiatives contribute to environmental responsibility and often result in cost savings. Embracing these practices aligns with the growing consumer demand for socially responsible business operations.

Employee Training and Engagement

Optimizing operation settings is not solely a technological endeavour — it requires the active participation of the workforce. Employee training programs play a crucial role in enhancing skills and fostering a culture of efficiency. Engaging employees in the continuous improvement process ensures that they become integral contributors to the optimization journey. This collaborative approach creates a sense of ownership and commitment to achieving efficiency goals.

Regular Performance Reviews and Adjustments

Efficiency is a dynamic attribute that requires constant attention and refinement. Regular performance reviews serve as the compass that keeps a business on the path of continuous improvement. These reviews comprehensively evaluate various performance metrics, including but not limited to production output, resource utilization, and energy consumption. Data-driven insights derived from these reviews clearly show how well the operation settings align with the established goals.

Furthermore, these reviews are not merely retrospective but a forward-looking mechanism. Businesses can anticipate potential challenges and opportunities by analyzing historical data and projecting future trends. This proactive approach allows for the formulation of strategic adjustments before issues escalate. For example, if a pattern of increased energy consumption is identified, steps can be taken to investigate and rectify the root cause before it significantly impacts operational costs.

Flexibility is a cornerstone of effective performance reviews. In a rapidly changing market, businesses must be agile in adapting to unforeseen challenges and opportunities. Whether influenced by technological advancements, shifts in consumer behaviour, or global economic conditions, the ability to pivot and adjust operation settings is vital. Flexibility enables businesses to respond swiftly to emerging trends and maintain a competitive edge in the industry.

A proactive approach to adjustments is crucial for the sustained success of an optimization strategy. Instead of waiting for performance metrics to deviate significantly from the desired targets, businesses should proactively identify improvement areas. This involves addressing existing inefficiencies and anticipating future needs and trends. By staying ahead of the curve, companies position themselves as industry leaders rather than followers, ensuring their optimization strategy remains dynamic and resilient.

Case Studies and Success Stories

Examining real-world examples of organizations that have successfully optimized their operation settings offers a treasure trove of insights for businesses seeking improvement. Case studies serve as practical roadmaps, illustrating the diverse ways efficiency can be achieved across different industries. These success stories showcase a variety of approaches, from technological innovations to streamlined workflows and sustainable practices.

Diving into case studies allows businesses to learn from the experiences of others, gaining valuable knowledge that can be applied to their unique circumstances. Understanding the challenges organizations face in similar or different industries provides a realistic perspective on the complexities of the optimization journey. Moreover, these studies often highlight the importance of adaptability, showcasing how successful organizations have adjusted their operation settings in response to evolving market conditions.

Examining success stories is not limited to celebrating achievements; it also involves dissecting the lessons learned from failures and setbacks. Understanding organizations' challenges in the optimization process provides a holistic view of the dynamics at play. By learning from triumphs and tribulations, businesses can develop a nuanced understanding of the potential pitfalls and opportunities on their path to efficiency.

In conclusion, regular performance reviews and exploring case studies are integral components of a holistic approach to optimizing operation settings. The former ensures that a business's strategy remains aligned with its goals and adapts to changing circumstances. At the same time, the latter provides tangible examples and valuable lessons from the real-world experiences of other organizations. Together, these practices empower businesses to navigate the complexities of the modern business landscape with resilience and foresight.

Final Say

Optimizing operation settings emerges as a strategic imperative for businesses across industries. From understanding current settings to implementing sustainable practices and engaging employees, the journey towards maximum efficiency is multifaceted. Through continuous data-driven adjustments and a commitment to improvement, businesses can position themselves not only to thrive in the present but also to navigate future challenges with resilience and agility. As the landscape evolves, the art of optimizing operation settings remains a cornerstone of sustained success.